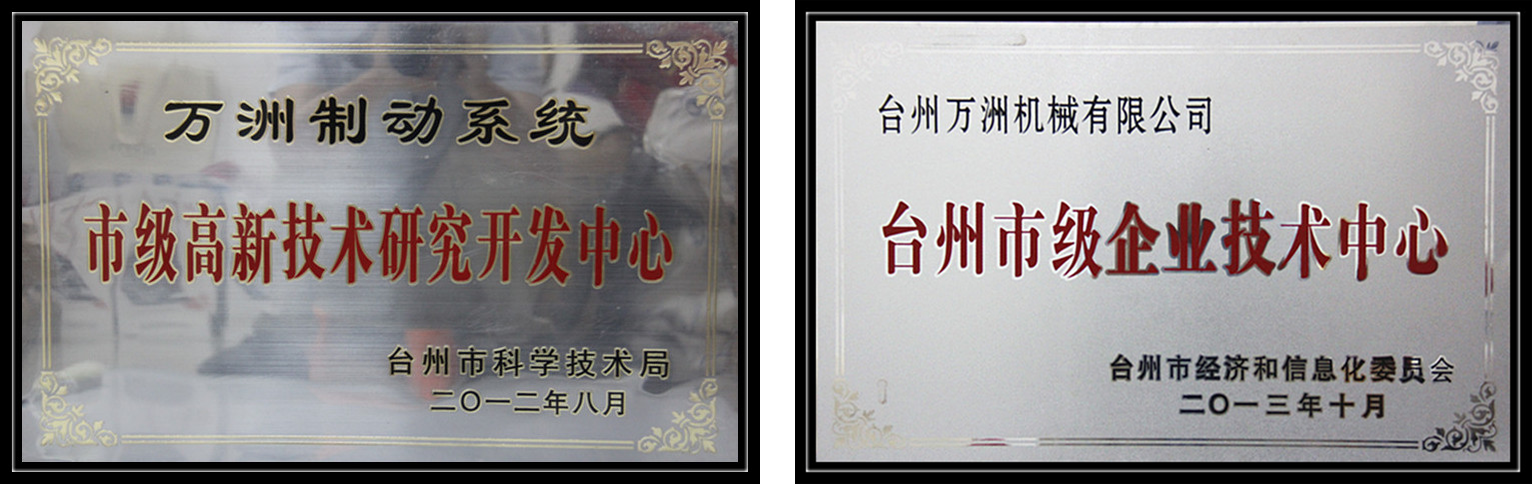

· Municipal R & D Center

· 15 Engineer

· 22 sets of testing equipment

......

|

Item |

Name |

Quantity |

|---|---|---|

|

1 |

Three coordinates |

1 |

|

2 |

Brinell, Rockwell and Vickers hardness machines |

3 |

|

3 |

Roughness tester |

1 |

|

4 |

Deflection instrument |

1 |

|

5 |

Deflectometer thickness tester |

1 |

|

6 |

Tensile test |

1 |

|

7 |

Carbon sulfur analyzer |

1 |

|

8 |

Visible spectrophotometer |

1 |

|

9 |

Salt spray tester |

1 |

|

10 |

Profilometer |

1 |

|

11 |

Microscope |

1 |

|

12 |

Flaw detector |

1 |

|

...... |

||

|

roughcast |

heat treatment |

surface treatment |

Salt spray test capability |

|---|---|---|---|

|

Forging (forged steel, forged aluminum) |

Induction quenching (high frequency, medium frequency and ultra audio frequency quenching) |

Galvanized |

No red rust in 1000 hours |

|

Casting (cast iron, cast steel, cast aluminum) |

Conditioning |

Hard chromium plating |

No red rust in 48 hours |

|

Cold heading |

Vacuum quenching |

Soft chromium plating |

No red rust after 120 hours |

|

Cold extrusion |

carburization |

plate with nickel |

No red rust in 48 hours |

|

Cold stamping |

Soft nitriding |

zn-ni |

No red rust in 1000 hours |

|

… |

Box type gas carburizing and nitriding furnace |

anodic oxidation |

No red rust in 1000 hours |

|

|

… |

Blackening |

No red rust in 16 hours |

|

|

|

Phosphating |

No red rust in 72 hours |

|

|

|

QPQ |

No red rust after 120 hours |

|

|

|

Soft nitriding |

96 hours without red rust |

|

|

|

dacromet |

No red rust in 1000 hours |

|

|

|

gold-plated |

No red rust after 120 hours |

|

|

|

Teflon |

friction coefficient0.05-0.1 |

|

|

|

electrophoresis |

No red rust after 120 hours |

|

|

|

… |

|